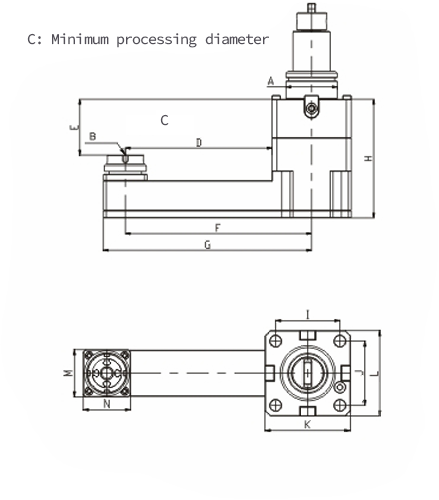

BMT65-NC Drive Tool Holder for Internal Groove

Dimensions:

A (in mm) – 65

B (collet) – ER16

C (in mm) – 80

D (in mm) – 153

E (in mm) – 60

F (in mm) – 200

G (in mm) – 270

H (in mm) – 127.5

I (in mm) – 70

J (in mm) – 73

K (in mm) – 94

L (in mm) – 94

M (in mm) – 47

N (in mm) – 47

Rotation speed – 5000 rpm

Speed ratio – 1:1

Free shipping on orders over $3000!

- Quality Assurance

- Fast shipping

- After-sale service

Description

| model | Locking method | A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| BMT55-NC | Internal lock | 55 | ER16 | 80 | 157.5 | 60 | 200 | 223.5 | 127.5 | 64 | 64 | 85 | 85 | 47 | 47 |

| BMT55-NC-D22 | Side lock | Tool diameter 3MM |

22 | 50 | 60 | 112.5 | 120.5 | 97.5 | 16 | 16 | |||||

| BMT55-NC-D25 | Side lock | Tool diameter 3MM |

25 | 67.5 | 51.5 | 110 | 118 | 73.5 | |||||||

| BMT65-NC | Internal lock | 65 | ER16 | 80 | 153 | 60 | 200 | 270 | 127.5 | 70 | 73 | 94 | 94 | 47 | 47 |

Drive Blocks for Internal Grooving

Drive units for internal groove machining BMT – a professional solution for complex technological tasks

In modern mechanical engineering, machining internal grooves requires special precision and reliability. BMT drive units are specially designed to perform these operations on CNC lathes, ensuring impeccable quality and high productivity.

Key Benefits

Technical features

✓ Hydraulic or mechanical tool locking

✓ Active cooling system

✓ Vibration and temperature monitoring sensors

✓ High speed capability

✓ Compatible with automatic tool change

Application areas

- Processing of keyways

- Cutting internal grooves

- Production of hydraulic components

- Manufacturing of parts for the aerospace industry

- Automotive industry

BMT – when every detail matters!