KN52 series 0-90° zero point quick change seat KN52-9052

Original price was: $599.00.$420.00Current price is: $420.00.

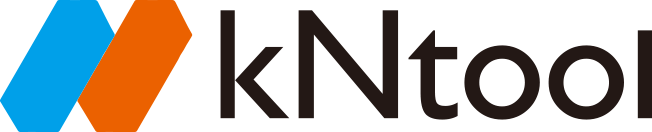

Size: 130*108*81mm

Material: aluminum + hardened stainless steel

Weight: 4.3kg

Locking force: 18KN

Locking method: 52 pull nails

*52/96 hole pitch compatible KT9652

*Using high-quality hardened aluminum, quick change and easy, accurate and durable, precise and wear-resistant, reducing costs and increasing efficiency.

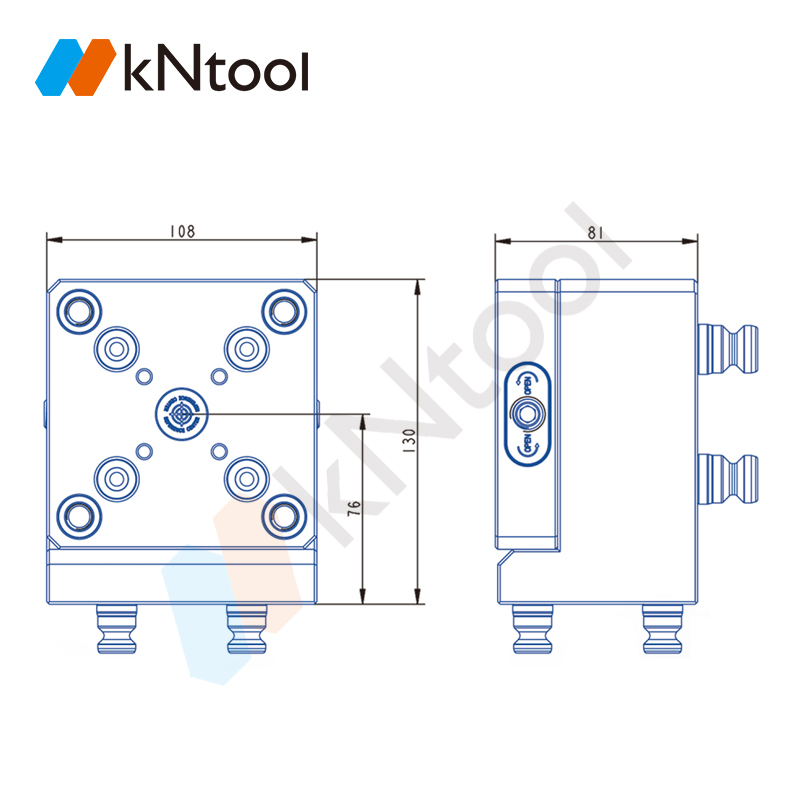

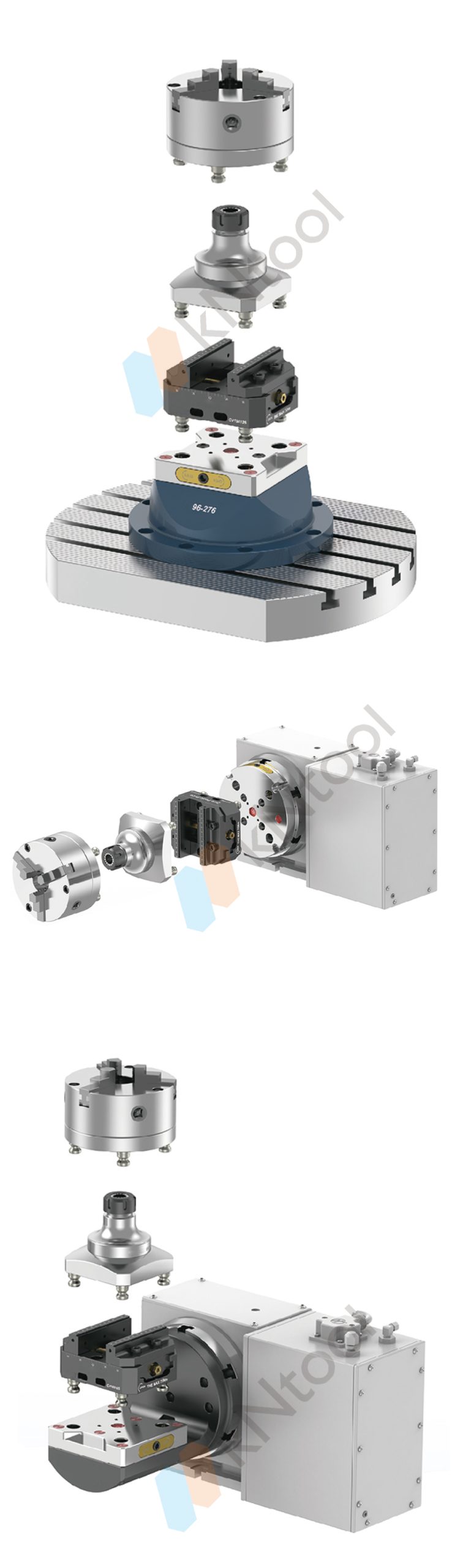

*Universal for three-, four- and five-axis machine tools.

*Repeat positioning accuracy 0.005mm

*Machine tool quick-change fixture

*Source manufacturer

Free shipping on orders over $3000!

- Quality Assurance

- Fast shipping

- After-sale service

Description

KN52 series 0-90° zero point quick change seat KN52-9052

KN52 series 0-90° zero point quick change seat KN52-9052

| Specification | 52 hole spacing manual 90° fixing seat KN52-9052 | 52 hole spacing manual 90° fixing seat KN96-9690 |

| Clamping force | 18KN | 22KN |

| Product Length | 130mm | 180mm |

| Product Material | Stainless steel | Stainless steel |

| Opening angle of the handle | 100° | 100° |

| Mounting hole diameter | 8mm | 10mm |

| Installation hole distance | 52mm | 96mm |

| Matching screws | M8 | M10 |

| Work schedule | 120mm | 120mm |

| Handle opening angle | 180° | 180° |

| Features | 90 degree zero point fixing seat | 90 degree zero point fixing seat |

| Scope of application | Workpiece positioning and clamping | Workpiece positioning and clamping |

| Product Type | Modular fixture system | Modular fixture system |

| Product thickness | 108mm | 130mm |

| Product Weight | 4.3KG | 12.8KG |

96mm/52mm hole distance zero point quick change plate

*Fast operation. *Flexible switching. *Precise positioning.

Use zero-point quick-change system to increase CNC machine tool clamping stations, improve processing capabilities and reduce downtime

Zero point quick change modular installation

The three-axis, four-axis, and five-axis high-precision zero-point fixtures are compatible with quick-release L-bridge plates, self-centering vises, ER collet holders, three-jaw chuck dovetail clamps, and various self-made fixtures, etc., to achieve quick change and quick installation, reduce the pre-machine preparation time, and ensure extremely high precision for repeated clamping of products and changing of processes. It is an upgraded version of the traditional processing technology, and significantly improves product efficiency and quality.

Additional information

| Weight | 5.5 kg |

|---|---|

| Dimensions | 130 × 108 × 81 cm |