BMT45-GC Gear Hobbing Driven Tool Holder

Original price was: $1,800.00.$1,675.00Current price is: $1,675.00.

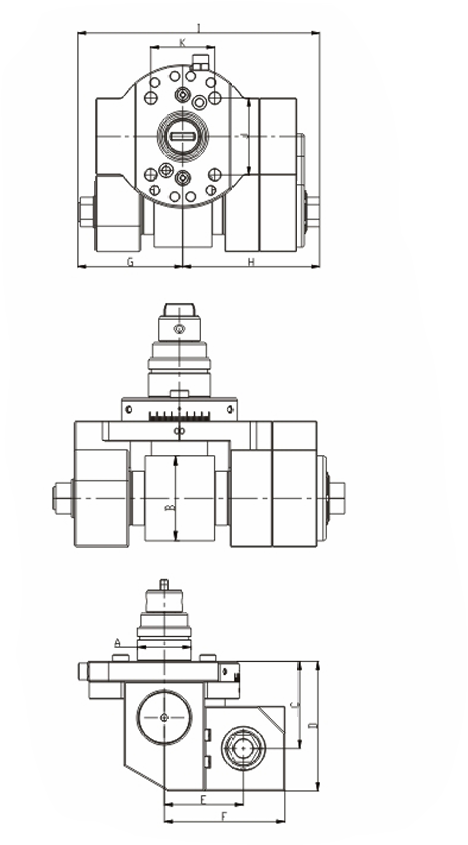

Dimensions:

A (in mm) – 45

B (in mm) – MAXØ70×70

C (in mm) – 73.5

D (in mm) – 105

E (in mm) – 60.5

F (in mm) – 91.5

G (in mm) – 90.5

H (in mm) – 115

I (in mm) – 205.5

J (in mm) – 58

K (in mm) – 58

Weight (kg) – 9.5

Rotation speed – 2000 rpm

Lower gear ratio – 2:1

Tilt angle adjustment – ±20º

Free shipping on orders over $3000!

- Quality Assurance

- Fast shipping

- After-sale service

Description

| model | A | B | C | 0 | E | F | G | H | 1 | J | K | N.W.(KG) |

| BMT40-GC | 40 | MAX φ65×55 | 65 | 96.5 | 59 | 90 | 82 | 107 | 189 | 60 | 50 | 8.3 |

| BMT45-GC | 45 | MAX φ70×70 | 73.5 | 105 | 60.5 | 91.5 | 90.5 | 115 | 205.5 | 58 | 58 | 9.5 |

| BMT55-GC | 55 | 64 | 64 | 9.8 | ||||||||

| BMT65-GC | 65 | 81 | 112.5 | 96 | 121 | 217 | 70 | 73 | 11.5 |

BMT Gear Hobbing Drive Blocks

BMT gear hobbing drive units – a professional solution for gear machining on CNC lathes

In modern mechanical engineering, gear processing requires special precision and productivity. BMT gear hobbing drive units allow high-precision cutting of teeth directly on CNC lathes, eliminating the need for additional equipment.

5 Key Benefits of BMT Gear Hobbing Units

🔹 High processing accuracy – tooth profile error does not exceed 0.01 mm

🔹 Versatility – ability to process cylindrical and bevel gears

🔹 Productivity – processing speed up to 300 teeth per minute

🔹 Compactness – integration into the existing machine system without modernization

🔹 Automation – compatibility with automatic tool change systems

Technical features

✓ Range of processed wheel modules: 1-12 mm

✓ Maximum processing diameter: 500 mm

✓ Active tool cooling system

✓ Load and vibration monitoring sensors

✓ Possibility of processing spur and helical gears

Application areas

Production of gearboxes and gearboxes

Manufacturing of gears for the automotive industry

Gear machining for machine tool industry

Production of parts for agricultural machinery

Aerospace industry

BMT – comprehensive solutions for gear machining operations!

Additional information

| Weight | 11 kg |

|---|

KN52 series manual circular zero point quick change plate KN52-170

KN52 series manual circular zero point quick change plate KN52-170